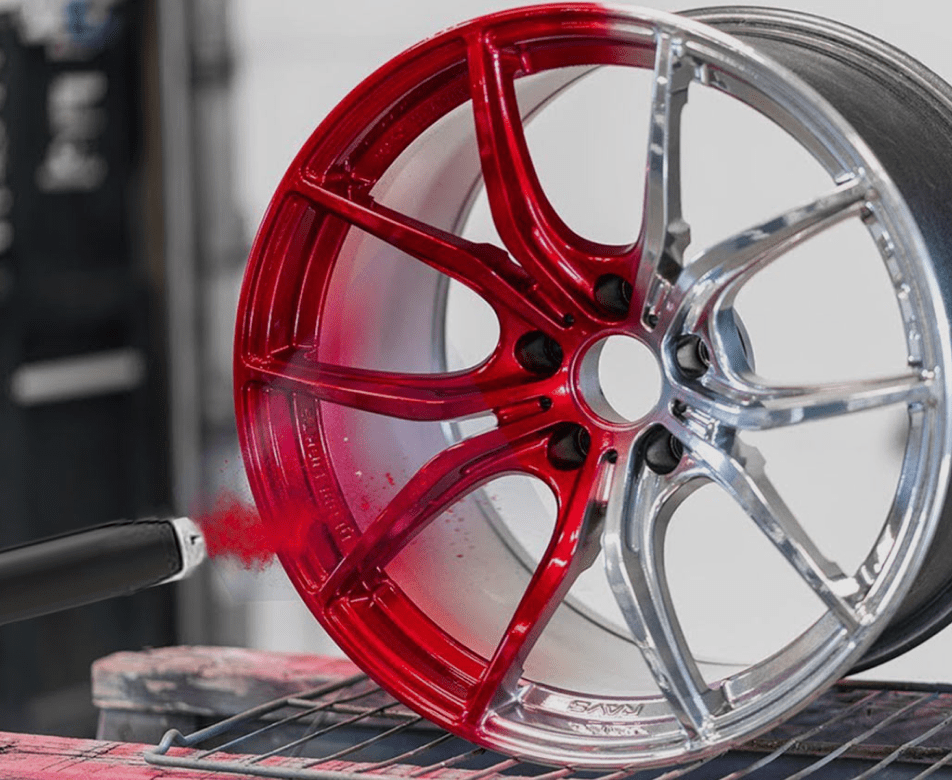

Transforming the look of your vehicle is easy when you turn to Aim Detailing. We specialize in automotive powder coating in Long Island, NY for all types of vehicle wheels and rims. Powder coating offers you an elevated and flawless look for your rims. Customization is easy as we offer a wide selection of different colors too!

Powder coating is the process of refinishing the rims on your vehicle. Our process is unique and specifically addresses all areas of your vehicle’s wheels and rims to ensure an even and flawless look. Take a look at our powder coating process below.

Wheel is first prepped. Any bends, or cracks are repaired. Bigger cracks can be tig welded.

Next, wheels are sand blasted and any curb rash, chips, dings, are reparied.

The face and barrel of the wheels are then powder coated to any color and finish desired.

Finally, wheels are mounted and balanced. Turn around time is usually 24 to 48 hours.

At Aim Detailing, we know how important it is for your vehicle to look its best – it is an extension of you after all. With that said, damage can happen, especially if you bump into a curb or rock that comes loose on the road and hits your vehicle.

With our powder coating services, you do not have to worry about damaged wheels or rims. Our services are designed to address these issues with our wheel refinishing services. Any and all damage to your wheels will be repaired prior to them being powder coated. We can fix rims, wheels, curb rash, warped rims, and bent rims.

Our technicians are skilled at rim refurbishing, and you can choose from more than 10,000 different color options. We offer a huge variety of options including candy finishes, texture, flat, matte, satin, high gloss, wrinkle, and hammer tones. We can even customize colors for you!

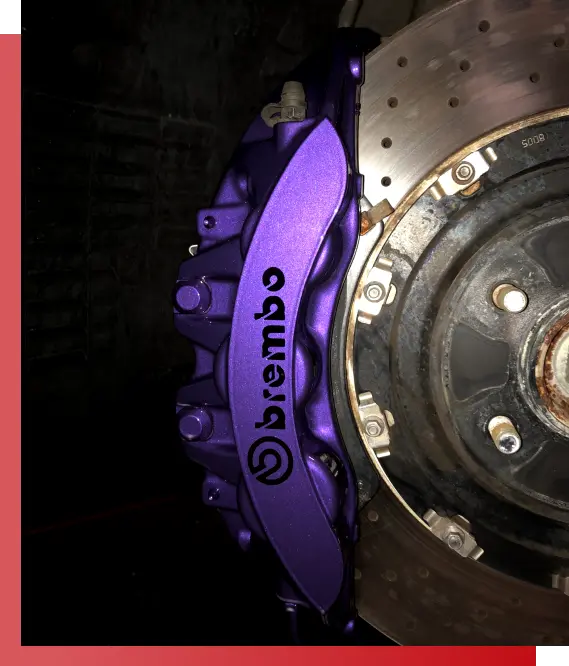

Caliper Painting and Liquid Wrap

Brake Caliper Painting and Liquid Wrap

We offer the flexibility to restyle your calipers in any color or finish of your choice, providing two distinct options. The first involves applying high-temperature resistant paint followed by a protective 2k clear coat, perfect for solid colors.

Alternatively, we offer custom removable liquid wrap options in various colors and finishes, also sealed with a durable 2k clear coat. This robust coating is rubberized, significantly enhancing resistance against chips and degradation over time while remaining fully removable when desired.